INTRODUCTION

What is Automation ?

Overview of Automation

Motivation

Automation in industry

Examples from different industry sectors

What is automation ?

Benefit of automation is that it saves labor; however,

it is also used to save energy and

materials and to improve quality, accuracy and precision.

Automation is basically the delegation of human control function to technical equipment for

Automation is basically the delegation of human control function to technical equipment for

1. Increasing productivity

2. Increasing robustness (consistency)

3. Reducing direct human labor costs and

expenses.

4. Increasing

quality

History of automation

Manual Control

Pneumatic Control

Hard wired logic

Control

Electronic

Control using Logic Gates

Programmable

Logic Controller

1. Manual Control

All

the actions related to process control are taken by the operators manually.

Disadvantage

Likely human errors and consequently its effect on

quality of final product.

The production, safety, energy consumption and usage of raw material are all subject to the correctness and accuracy of human action.

The production, safety, energy consumption and usage of raw material are all subject to the correctness and accuracy of human action.

2. Pneumatic Control

Industrial automation, with its machine and process

control, had its origin in the 1920s with the advent of "Pneumatic

Controllers“.

Actions were

controlled by a simple manipulation of pneumatic valves, which in turn were

controlled by relays and switches.

Disadvantage

Bulky and Complex

System

Involves lot of

rework to implement control logic

Longer project

time

3. Hard wired logic Control

The contactor and relays together with hardware timers and counters were used in achieving the desired level of automation

Disadvantage

Bulky panels

Complex wiring

Longer project time

Difficult maintenance and troubleshooting

Difficult maintenance and troubleshooting

4. Electronic Control using Logic Gates

In 1960s with the advent of electronics, the logic gates started replacing the relays and

auxiliary contactors in the control circuits.

auxiliary contactors in the control circuits.

The hardware timers & counters were replaced by

electronic timers.

Advantage

Disadvantage

Reduced space requirements

Energy saving

Less maintenance & greater reliability

Less maintenance & greater reliability

Disadvantage

Changes in control logic not possible

More project time

More project time

5. Programmable Logic Controller

In 1970s with the

coming of microprocessors and associated peripheral chips, the whole process of

control and automation underwent a

radical change.

Instead of

achieving the desired control or automation through physical wiring of control

devices, in PLC it is achieved through a

program or say software.

The programmable

controllers have in recent years experienced an unprecedented growth as

universal element in Industrial Automation.

It can be effectively used in applications ranging from simple control like replacing small number of relays to complex automation problems.

It can be effectively used in applications ranging from simple control like replacing small number of relays to complex automation problems.

Advantages of PLCs

Reduced space

Energy saving

Ease of

maintenance

Economical

Greater life

& reliability

Tremendous

flexibility

Shorter project

time

Easier storage,

archiving and documentation

Industrial automation main components

Field instrumentsControl hardware

Control software

Automation : Typical installation...

Automation : Typical installation...

Sensors or Transducers (Field Instruments)

Sensors are used to sense the changes in physical

parameter like Temperature, Level, Flow, Humidity, Pressure and many others..

Transducers are

used to convert not electrical quantity to electrical signals

Hence it

concludes, sensors and transducers are placed in field to sense the physical

parameters and send the electrical signal of respective changes to control

rooms.

These signal are

either digital or analog signals for example, Ohm(RTD), mv(Thermocouple), standard 4-20mA signal, etc.

Widely used field instruments in industries

Flow transmitters

(Orifice, Ventury, Electromagnetic flow meter etc)

Pressure

transmitters (Bourdon gauge, Bellows, Diaphragm, etc)

Temperature

transmitters (Thermocouple, RTD, Thermister, etc)

Level Transmitter

(Ultrasonic transmitter, Radar type, capacitive type)

pH transmitter

Conductivity

Meter...etc

Famous manufacturing companies (Field instruments)

Fisher Rosemount

Yokogawa

Endress+Hauser

Forbes Marshall

Honeywell ABB

Yokogawa

Endress+Hauser

Forbes Marshall

Honeywell ABB

Control hardware

Standalone PID

Controllers

Programmable logic controllers

Distributed control system

Programmable logic controllers

Distributed control system

1. Standalone PID Controllers

This can be installed in field or in control room

Every companies have variations in programming patterns to setup PID configuration

Typical installation of standalone PID controller

Famous manufacturing companies in PID controllers

ABB

Yokogawa

Moore

Forbes Marshall

Honeywell

Eurotherm

ASCON

Yokogawa

Moore

Forbes Marshall

Honeywell

Eurotherm

ASCON

2. Programmable logic controllers

A programmable logic

controller (PLC), or programmable controller is an industrial

digital computer which has been ruggedized and adapted for the control of

manufacturing processes, such as assembly lines, or robotic devices, or any activity that

requires high reliability control and ease of programming and process fault

diagnosis.

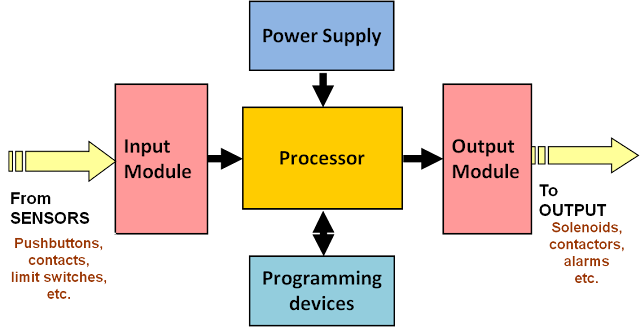

What is inside PLC ?

|

| Architecture of PLC |

A programmable logic controller (PLC), is a like a microcontroller which is used for doing so many applications.

It basically

consist of

1. CPU with

processor and program memory

2. Power supply

3. Input module

4. Output module

5. Control bus

1. Parts of Delta PLC

2. Parts of Allen Bradley PLC

3. Parts of Siemens PLC

4. Parts of Zelio Schneider electric PLC

Distribution of I/O's through controller

Distributed control system (DCS)

|

| General architecture of DCS |

System cabinets and Marshalling cabinets of DCS

|

| System and Marshalling cabinet arrangement |

Various DCS and Hybrid DCS providing companies

DCS

1. Yokogawa (Centum VP)

2. Honeywell (EPKS)

3. Emerson (Delta V)

4. Forbes Marshall

Hybrid DCS

1. Allen Bradley (Compact logix and control logix)

Various Communication protocol used in DCS or PLC systems and its hierarchy

LAN (Ethernet)

Modbus, CAN,

Serial communication

OPC (OLE for

Process Control)

Control NET

Foundation Field

bus

Profibus (DP,PA)

Device NET

Various languages used in PLC and DCS

Ladder Logic ( LAD/LD)

Function Block

Diagram (FBD)

Sequential

Function Chart (SFC)

Structured Text

(ST)

Instruction List

(IL )

Supervisory Control and Data Acquisition software (SCADA)

SCADA (supervisory control and data acquisition) is a category of

software application program for process control, the gathering of data in real

time from remote locations in order to control equipment and conditions.

Features of typical SCADA software

Dynamic process graphic

Real-time and Historical trending

Alarms

Recipe Management

Security

Device connectivity

Script for logic development

Database connectivity

Displays used for monitoring in SCADA systems

Some SCADA software available in market

Intouch (Wonderware factory suit)

Wincc (Siemens)

Simplicity (GE Fanuc)

Core

branches/career of Instrumentation and its scope in Industry

JOB OPTIONS

EPC

Engineering

Procurement and construction

Designing of

total plant

Automation work

includes in EPC companies

Designing of

P&ID drawings

Automation

Designing of the

Automation system

Erection and

Commissioning

Maintenance and

Troubleshooting of existing system