What is Device Net?

Device Net, like other CIP Networks, follows the Open Systems Interconnection (OSI) model, which defines a framework for implementing network protocols in seven layers: physical, data link, network, transport, session, presentation and application. Networks that follow this model define a complete suite of network functionality from the physical implementation through the application or user interface layer. As with all CIP Networks, Device Net implements CIP at the Session layer and above while adapting CIP to the specific Device Net technology at the Transport layer and below. This network architecture is shown in Figure below.

The Device Net network infrastructure is passive, making node functionality independent of physical location and the network itself inherently tolerant to individual lost node connections. Although the network infrastructure is passive, the network cable can convey device power over the same cable with communication messages. This feature is extremely valuable for devices with small physical size and power requirements, such as photo cells, where Device Net simplifies the number of required system components and connections. To further decrease complexity, Device Net systems require only a single point of connection for both configuration and control. This is because Device Net supports both I/O (or implicit) messages—those that typically contain time-critical control data—and explicit messages— those in which the data field carries both protocol information and specific service requests.

And, as a producer-consumer network that supports multiple communication hierarchies

and message prioritization, Device Net provides more efficient use of bandwidth than a device network based on a source-destination model. Device Net systems can be configured to operate either in a master/slave or distributed control architecture using peer-to-peer communication.

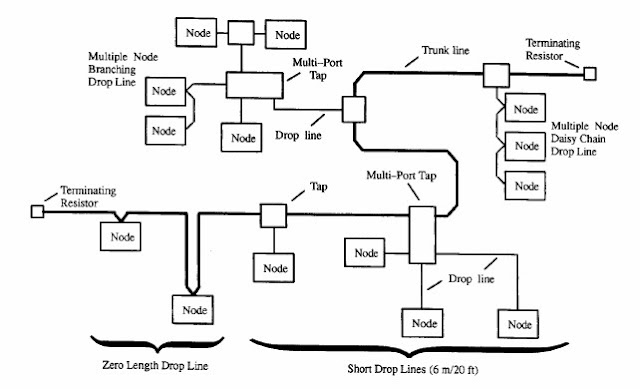

The Physical Layer Device Net incorporates a trunk line drop line topology that allows the use of separate twisted pair buses for both signal and power distribution. The possible variants of this topology are shown in Figure below.

Nodes can be removed or inserted with the network on, helping to reduce production downtime. Power taps can be added at any point on the network, enabling the use of redundant power supplies. The trunk line current rating is 8 Amps maximum, depending on cable type. Device Net supports three possible data rates, and the user may choose from several cable options. In general, these cables can be used as trunk line or as drop line, but end-to-end network length will vary depending on the cable type selected and the date rate used, as shown in Table below.

The Data Link Layer

Device Net uses standard, unmodified CAN for its Data Link layer. The relatively minimal

overhead required by CAN at the Data Link layer makes DeviceNet efficient in message

handling. Minimal network bandwidth is used to package and transmit CIP messages over

DeviceNet, and minimal processor overhead is required by a device to parse such

messages. The format for the CAN data frame is shown in Figure below.

The Network and Transport Layers

Device Net is a connection-based network, meaning that a relationship (i.e., connection)

with a device must first be established in order to exchange data with that device. Connections are established via either an Unconnected Message Manager (UCMM) or a Group 2 Unconnected Port. In addition, Device Net supports two types of messages, Explicit and Implicit (often referred to as I/O Messages). Explicit messages are used for request/response-oriented transactions typically associated with configuration or data collection that are not time critical, whereas Implicit messages are used to communicate real-time I/O data.

For software communication Demo Please go to through following link.

Click here (This video is not in English language)

For Extra Details go through following PDF/PPT.

Click here 1

Click here 2

Click here 3

Device Net, like other CIP Networks, follows the Open Systems Interconnection (OSI) model, which defines a framework for implementing network protocols in seven layers: physical, data link, network, transport, session, presentation and application. Networks that follow this model define a complete suite of network functionality from the physical implementation through the application or user interface layer. As with all CIP Networks, Device Net implements CIP at the Session layer and above while adapting CIP to the specific Device Net technology at the Transport layer and below. This network architecture is shown in Figure below.

|

| Device Net Adaption of CIP |

And, as a producer-consumer network that supports multiple communication hierarchies

and message prioritization, Device Net provides more efficient use of bandwidth than a device network based on a source-destination model. Device Net systems can be configured to operate either in a master/slave or distributed control architecture using peer-to-peer communication.

The Physical Layer Device Net incorporates a trunk line drop line topology that allows the use of separate twisted pair buses for both signal and power distribution. The possible variants of this topology are shown in Figure below.

|

| Device Net Topology Options |

|

| Device Net end-to-end network distance as a function of data rate and cable type |

The Data Link Layer

Device Net uses standard, unmodified CAN for its Data Link layer. The relatively minimal

overhead required by CAN at the Data Link layer makes DeviceNet efficient in message

handling. Minimal network bandwidth is used to package and transmit CIP messages over

DeviceNet, and minimal processor overhead is required by a device to parse such

messages. The format for the CAN data frame is shown in Figure below.

|

| CAN Data Frame Format |

Device Net is a connection-based network, meaning that a relationship (i.e., connection)

with a device must first be established in order to exchange data with that device. Connections are established via either an Unconnected Message Manager (UCMM) or a Group 2 Unconnected Port. In addition, Device Net supports two types of messages, Explicit and Implicit (often referred to as I/O Messages). Explicit messages are used for request/response-oriented transactions typically associated with configuration or data collection that are not time critical, whereas Implicit messages are used to communicate real-time I/O data.

|

| Device Net Allocations within the 11-bit CAN Identifier Field |

For software communication Demo Please go to through following link.

Click here (This video is not in English language)

For Extra Details go through following PDF/PPT.

Click here 1

Click here 2

Click here 3

1 comments:

Write commentsa place for get better market insights and understand needs

Replyhttps://digiosense.com/

EmoticonEmoticon